Hazmat operations involve the safe handling, identification, and mitigation of hazardous materials incidents. This guide provides foundational knowledge, emphasizing training, regulations, and responder safety protocols to ensure effective emergency responses.

1.1. Overview of Hazardous Materials (Hazmat)

Hazardous materials, or Hazmat, are substances that pose risks to people, the environment, or property due to their chemical, physical, or biological properties. These materials are classified into distinct hazard classes, such as explosives, gases, flammable liquids, and toxic substances. Understanding their properties and potential dangers is crucial for safe handling, transportation, and emergency response. Proper identification and classification ensure compliance with regulations like NFPA guidelines, facilitating effective risk management and mitigation strategies.

1.2. Importance of Hazmat Training

Hazmat training is essential for emergency responders to manage hazardous materials incidents safely and effectively. It equips personnel with the knowledge to recognize hazards, use personal protective equipment (PPE), and apply regulatory standards. Proper training reduces the risk of accidents, environmental damage, and exposure to toxic substances. Regular, updated instruction ensures responders stay compliant with safety protocols, enhancing their ability to protect people, property, and the environment during Hazmat emergencies.

1.3. Key Regulations and Standards (e.g., NFPA 472)

Regulations like NFPA 472 establish standards for hazardous materials response, ensuring competency and safety. These guidelines define roles, training requirements, and operational protocols, helping responders manage incidents effectively. Compliance with these standards ensures consistent, safe practices across all levels of Hazmat operations, minimizing risks to personnel, the public, and the environment. Adherence to these regulations is critical for legal and operational compliance.

Hazard Identification and Classification

Hazard identification and classification involve recognizing incidents, categorizing materials into hazard classes, and using tools like MSDS for critical information to ensure safe handling and response.

2.1. Recognizing Hazmat Incidents

Recognizing hazmat incidents requires responders to identify signs such as unusual odors, leaking containers, or distressed individuals. Early detection is critical to prevent escalation and ensure safety.

2.2. Understanding Hazard Classes and Divisions

Hazardous materials are categorized into nine primary classes and further divided into specific divisions. Classes include explosives, gases, flammable liquids, and oxidizers, among others. Understanding these classifications is crucial for identifying risks and selecting appropriate response strategies. Each class is marked with unique symbols and numbers, aiding responders in quickly identifying hazards. Proper identification ensures safe handling and mitigation of incidents, making this knowledge essential for effective hazmat operations.

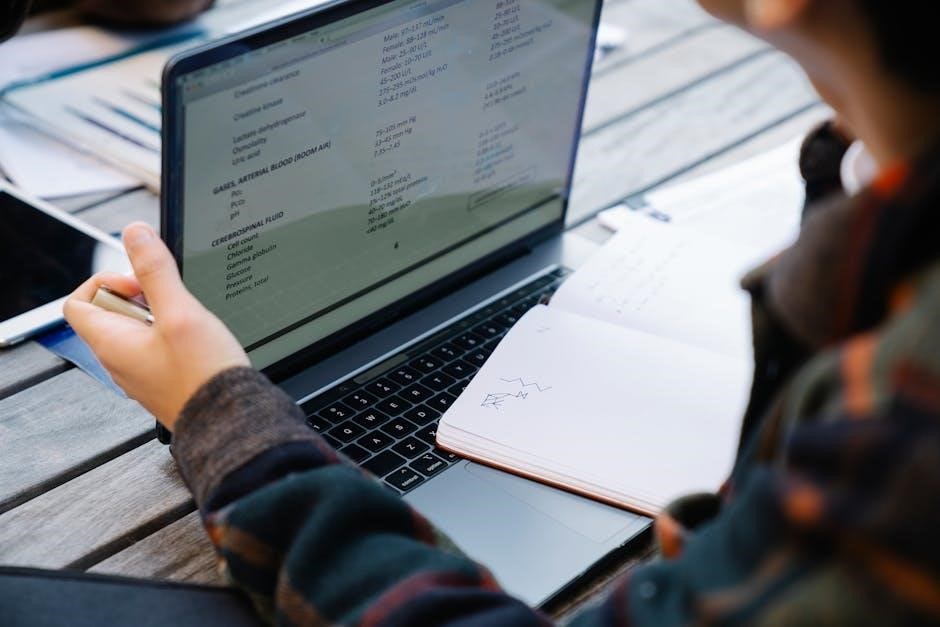

2.3. Role of Material Safety Data Sheets (MSDS)

Material Safety Data Sheets (MSDS) provide critical information about hazardous materials, including chemical composition, health hazards, and safe handling procedures. They are essential for risk assessment, PPE selection, and emergency response planning. MSDS details first aid measures, fire-fighting techniques, and environmental impact, ensuring responders can mitigate incidents effectively. Compliance with regulations and standards often requires MSDS availability, making them a vital resource for hazmat operations and ensuring the safety of both responders and the environment.

Risk Assessment and Safety Protocols

Risk assessment is critical in hazmat operations to evaluate potential hazards and implement safety measures. Protocols ensure responder safety, proper PPE use, and effective decontamination procedures.

3.1. Evaluating Potential Hazards

Evaluating potential hazards in hazmat operations involves identifying the type, quantity, and state of materials. This includes analyzing toxicity, flammability, and reactivity. Responders must assess contamination risks, environmental impacts, and exposure pathways. Accurate hazard evaluation ensures appropriate safety measures and response strategies. Tools like Material Safety Data Sheets (MSDS) and hazard classification systems aid in this process. Proper evaluation minimizes risks to personnel, the public, and the environment, ensuring effective incident management and mitigation.

3.2. Personal Protective Equipment (PPE) Selection

Personal Protective Equipment (PPE) selection is critical in hazmat operations to ensure responder safety. PPE is chosen based on the type of hazardous material, exposure risk, and the level of protection required. Levels of PPE, from Level A (full encapsulation) to Level D (minimal protection), are defined by NFPA 472. Proper fit, respirator use, and compatibility with other equipment are essential. Always follow manufacturer guidelines and standards to maximize protection and minimize risks during hazardous material incidents.

3.3. Decontamination Procedures

Decontamination is a critical step in hazmat operations to remove or neutralize hazardous substances from personnel, equipment, and surfaces. Procedures include assessment, isolation, and cleaning using methods like chemical neutralization or physical removal. NFPA 472 guidelines emphasize proper techniques to prevent re-contamination and ensure safety. Effective decontamination protects responders, reduces environmental impact, and restores equipment for future use, adhering to established safety protocols and standards.

Emergency Response and Operations

Hazmat emergency response involves a structured approach to mitigate risks, protect lives, and minimize environmental impact. It requires coordinated actions, adherence to safety protocols, and effective communication.

4.1. Awareness Level Response

Awareness level response involves recognizing the presence of hazardous materials and initiating appropriate actions. It requires identifying potential risks, securing the area, and notifying higher-level responders. Personnel at this level are trained to recognize hazards but not to intervene directly. Their role is to ensure safety by maintaining a safe distance, preventing contamination spread, and providing critical information to operational teams. Proper communication and adherence to safety protocols are essential to prevent escalation and protect both responders and the public.

4.2. Operational Level Response

Operational level response involves taking direct action to control and mitigate hazardous materials incidents. Responders at this level are trained to implement containment and mitigation strategies using specialized equipment and techniques; They assess the situation, select appropriate countermeasures, and execute tactical operations to neutralize threats. This level requires a deeper understanding of hazardous materials behavior, advanced PPE usage, and adherence to safety protocols. Effective communication and coordination with the incident command system are critical to ensure safe and efficient operations.

4.3. Technician Level Response

Technician level response involves advanced operations requiring specialized training and equipment. Responders at this level perform detailed hazard assessments, conduct air monitoring, and implement complex mitigation techniques. They operate specialized tools for containment, confinement, and neutralization of hazardous materials. Technician-level personnel take a hands-on approach to stabilize incidents, often working in high-risk environments. Their expertise ensures the safe execution of tactical operations, coordinating with higher-level responders when necessary to achieve incident resolution effectively.

Communication and Coordination

Effective communication and coordination are critical in hazmat operations, ensuring seamless collaboration among responders, agencies, and stakeholders. Clear protocols, standardized terminology, and real-time information sharing enhance incident management and safety.

5.1. Incident Command System (ICS)

The Incident Command System (ICS) is a standardized framework for managing emergencies, ensuring clear communication and coordination. It establishes a chain of command, roles, and responsibilities, enabling effective decision-making. ICS promotes unity of effort among responders, agencies, and stakeholders. Key components include the Incident Commander, Unified Command, and span of control. Proper ICS implementation ensures efficient resource allocation, operational safety, and adherence to protocols, critical for successful hazmat incident management and minimizing risks to personnel and the public.

5.2. Effective Communication Strategies

Effective communication is critical in hazmat operations to ensure coordination and safety. Clear, concise messaging and standardized terminology help prevent misunderstandings. Regular updates and briefings keep all stakeholders informed. Communication systems, such as radios and incident command tools, facilitate real-time information sharing. Role-specific updates ensure relevant data reaches the right personnel. Visual aids, like maps and diagrams, enhance understanding. These strategies promote seamless coordination, enabling swift and informed decision-making during hazardous materials incidents, ultimately protecting responders and the public.

5.3. Coordination with Emergency Services

Coordination with emergency services is essential for effective hazmat incident management. Integration with police, fire, and medical teams ensures a unified response. The Incident Command System (ICS) facilitates structured communication and resource allocation. Joint assessments and shared situational awareness enhance operational efficiency. Regular updates and defined roles minimize conflicts, ensuring seamless collaboration. This coordinated effort optimizes safety, accelerates resolution, and reduces risks to responders and the public during hazardous materials incidents;

Storage, Handling, and Transportation

Proper packaging, labeling, and safe handling practices are critical for storing and transporting hazardous materials, ensuring compliance with regulations and minimizing risks to people and the environment.

6.1. Proper Packaging and Labeling

Proper packaging ensures hazardous materials are contained safely, preventing leaks or spills during transport. Labeling must clearly identify contents and hazards, using standardized symbols and text. Compliance with UN packaging specifications and regulatory labeling requirements is mandatory. Proper labeling aids in quick hazard identification by emergency responders. Correct packaging materials and secure closures are essential to prevent accidental release. Improper packaging or labeling can lead to legal penalties and increased risks of accidents. Always verify packaging integrity before transport or storage.

6.2. Safe Handling Practices

Safe handling practices are critical to minimize risks when managing hazardous materials. Always use appropriate personal protective equipment (PPE) and ensure equipment is in good condition. Proper lifting techniques and secure handling methods prevent accidental spills or exposure. Regular training on material-specific handling is essential. Follow established safety protocols and emergency response plans. Proper ventilation and use of tools designed for hazardous materials are key. Always verify material compatibility with containers and tools to prevent chemical reactions. Adherence to these practices ensures safety and regulatory compliance.

6.3; Transportation Regulations

Transportation of hazardous materials must comply with strict federal and international regulations to ensure public safety. Proper labeling, packaging, and documentation are essential to prevent accidents and legal issues. Materials must be classified according to their hazard level, and vehicles must display appropriate placards. Drivers and handlers should receive specific training on transportation safety and emergency procedures. Regular inspections of containers and vehicles are mandatory. Adherence to these regulations minimizes risks and ensures compliance with legal standards for hazmat transport.

Training and Certification

Hazmat training and certification are crucial for responders to handle hazardous materials safely. Annual refresher courses and specialized programs ensure compliance with regulations and enhance operational skills.

7.1. Annual Refresher Training Requirements

Annual refresher training is mandatory for all Hazmat responders to maintain certification. Courses cover updated protocols, regulatory changes, and practical exercises to ensure proficiency in handling hazardous materials incidents effectively. This continuous learning reinforces safety standards, operational techniques, and emergency response strategies, aligning with federal regulations and industry best practices to minimize risks and enhance team preparedness.

7.2. Certification Programs for Hazmat Responders

Certification programs for Hazmat responders ensure standardized competence levels. These programs, often aligned with NFPA 472, offer structured training in awareness, operations, and technician levels. They cover hazard identification, risk assessment, and response techniques. Certifications validate responders’ ability to safely and effectively manage Hazmat incidents, adhering to regulatory requirements and enhancing team reliability during emergencies.

7.3. Continuous Skill Development

Continuous skill development is essential for Hazmat responders to stay updated on evolving threats and technologies. Refresher training, simulations, and hands-on exercises ensure proficiency. Collaboration with experts and sharing best practices enhance readiness. Regular updates on new materials and response strategies are critical. Ongoing training fosters adaptability, enabling responders to handle diverse incidents effectively while maintaining compliance with safety standards and regulations.