A blower motor wiring diagram is a detailed guide illustrating the electrical connections for installing and troubleshooting blower motors in HVAC systems. It ensures safe, efficient operation by providing clear wire color codes, component locations, and step-by-step instructions. Always consult the specific diagram for your motor model to avoid errors and ensure proper functionality. This manual will walk you through understanding and working with these essential diagrams.

Tools and Materials Needed for Wiring

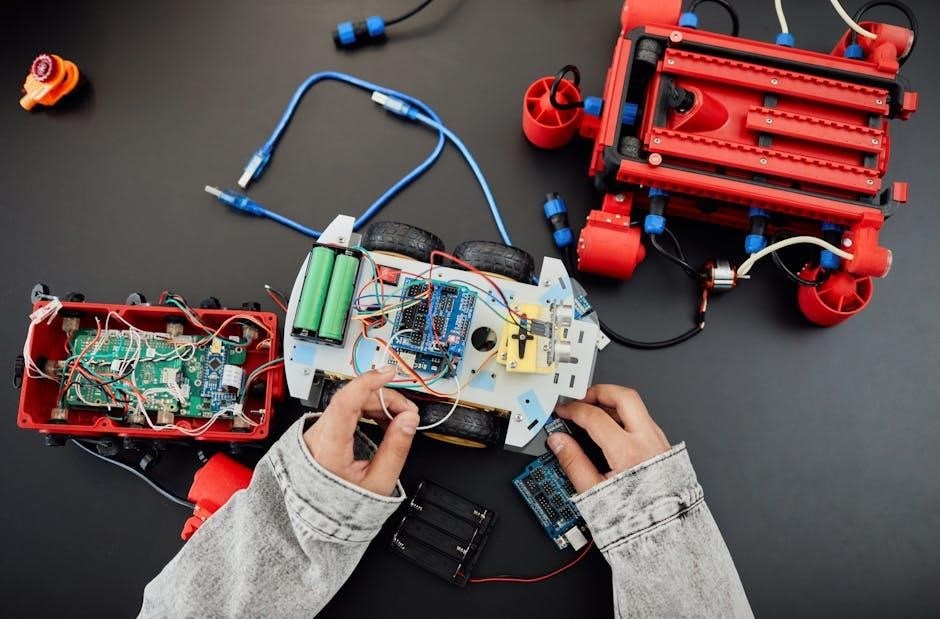

Essential tools include a wire stripper, screwdriver, pliers, and wire nuts. Materials needed are replacement wires, connectors, and electrical tape for secure connections.

- Wire stripper

- Screwdriver

- Pliers

- Wire nuts

- Electrical tape

- Replacement wires

- Connectors

2.1 Essential Tools

Essential tools for wiring a blower motor include a wire stripper, screwdriver, pliers, and electrical tape. These tools help in safely and efficiently connecting wires. Start with a wire stripper to remove insulation from wires, ensuring clean connections. A screwdriver is necessary for securing wires to terminals, while pliers assist in bending or gripping wires. Electrical tape is used to insulate and protect connections from damage. Having these tools ready ensures a smooth wiring process. Always use high-quality tools to avoid stripped screws or damaged wires. Proper preparation prevents delays and ensures safety during installation.

2.2 Materials Needed

Key materials for wiring a blower motor include wire nuts, electrical tape, and a wiring diagram specific to your motor model. Wire nuts securely connect wires, while electrical tape insulates and protects connections. A capacitor may also be required, depending on the motor type. Ensure all materials are compatible with your system’s voltage and current ratings. Additional items like heat shrink tubing or wire connectors can enhance durability and safety. Always refer to the manufacturer’s guidelines for specific material recommendations. Gathering these materials beforehand ensures a smooth and efficient wiring process.

Understanding the Blower Motor Wiring Diagram

A blower motor wiring diagram visually represents the electrical connections, components, and their relationships. It simplifies installation and troubleshooting by clarifying wire functions and proper connections.

3.1 Key Components of the Diagram

The blower motor wiring diagram includes essential components such as the motor itself, capacitor, transformer, and control module. It also details power supply lines, neutral wires, and ground connections. The diagram highlights terminal points, wire color codes, and specific functions like speed settings. Additionally, it shows how relays and switches integrate with the system. Understanding these components is crucial for accurate wiring and safe operation. Always refer to the diagram for specific configurations, as variations exist between models and manufacturers.

3.2 Wire Color Coding

Wire color coding is a critical aspect of blower motor wiring, as it identifies the function of each wire. Common colors include black (high speed), blue (medium speed), and red (low speed). Brown and white wires often connect to the capacitor, while others may serve as neutral or control wires. These colors help technicians and DIYers make accurate connections. However, color codes can vary by manufacturer, so always consult the specific wiring diagram for your motor. Properly interpreting wire colors ensures safe and efficient installation, preventing potential electrical hazards or motor damage. Always double-check the diagram to confirm wire functions before making connections.

Step-by-Step Wiring Installation

Step-by-step wiring installation involves connecting power, neutral, and control wires, ensuring proper grounding and secure connections. Use appropriate tools and follow safety guidelines for efficient installation.

4.1 Connecting the Power Supply

Connecting the power supply to the blower motor involves identifying the high-speed (usually black) and neutral (white) wires. Always consult the wiring diagram to verify colors. Strip the ends of the wires using a wire stripper and connect them to the motor terminals. Ensure the connections are secure and insulated with electrical tape or wire nuts. If the motor uses a capacitor, connect the appropriate wires to the capacitor terminals as specified in the diagram. Double-check the connections to avoid short circuits. Finally, verify that the power source is correctly linked to the motor, ensuring safe and efficient operation.

4.2 Neutral and Control Wires

After connecting the power supply, focus on the neutral and control wires. The neutral wire (usually white) completes the circuit, while control wires regulate motor speed and operation. Refer to the wiring diagram to identify these wires, as colors may vary (e.g., red for low speed, blue for medium, and black for high). Connect the neutral wire to the designated terminal on the motor. For control wires, ensure they are linked to the appropriate components, such as the thermostat or speed controller. Use wire nuts or electrical tape to secure connections. Double-check all links to prevent short circuits and ensure proper functionality; Always turn off the power supply before making adjustments.

4.3 Testing the Motor

After completing the wiring connections, test the blower motor to ensure proper operation. Start by turning on the power supply and checking if the motor runs smoothly. Verify that the motor operates at the correct speed and direction. Use a multimeter to measure voltage at the terminals to confirm it matches the rated voltage. Check for any unusual noises or vibrations, which could indicate misalignment or wiring issues. Test all speed settings if your motor is variable speed. Ensure the motor stops and starts correctly when controlled by the thermostat or control panel. If the motor does not run, review connections and consult the wiring diagram for potential errors. Proper testing ensures safety and efficiency before final installation.

Troubleshooting Common Wiring Issues

Troubleshooting blower motor wiring issues involves checking power supply, connections, and control circuits. Ensure correct voltage with a multimeter and inspect for loose or damaged wires. Verify wire colors match the diagram. If the motor runs when powered directly but not via controls, examine relays and switches. Test the capacitor for faults. Consult the wiring diagram for accuracy and manufacturer instructions for specific guidance. Addressing each component systematically helps identify and resolve issues efficiently.

5.1 Identifying Common Problems

Common issues with blower motor wiring include power supply faults, loose connections, and incorrect wire color assignments. Motor failure to start may indicate a blown fuse or tripped breaker. Check for open circuits using a multimeter. Damaged or frayed wires can cause intermittent operation. Verify the capacitor is functioning properly, as a faulty one can prevent motor startup. Ensure control signals from thermostats or switches are correct. Referencing the wiring diagram helps pinpoint mismatches in wire connections. Addressing these issues systematically ensures reliable motor operation and prevents further damage to the system. Always follow safety guidelines when diagnosing electrical components.

5.2 Advanced Diagnostic Techniques

Advanced diagnostic techniques involve using specialized tools like multimeters and oscilloscopes to analyze electrical signals and currents. Measure voltage at the motor terminals to ensure it matches the rated specifications. Check for short circuits or open circuits in the wiring harness. Use a multimeter to test resistance and continuity in the windings and capacitor. Analyze the capacitor’s start and run currents with an oscilloscope to detect irregularities. Inspect the wiring diagram for complex systems to identify potential feedback loops or control signal interference. These methods help pinpoint elusive issues, such as intermittent faults or phase imbalances, ensuring precise repairs and optimal motor performance.

Safety Precautions and Best Practices

Always disconnect power before starting work to avoid electrical shocks. Use insulated tools and wear protective gear like gloves and safety glasses. Follow the wiring diagram precisely to prevent incorrect connections. Double-check all wires for damage or wear. Ensure the motor is properly grounded to avoid hazards. Use appropriate tools to avoid stripping wires or causing damage. Keep the workspace clean and well-lit to reduce accidents. Refer to the manufacturer’s instructions for specific safety guidelines. Never bypass safety devices like fuses or circuit breakers. Test the system step-by-step after wiring to ensure everything functions safely and correctly.

Manufacturer-Specific Wiring Diagrams

Manufacturer-specific wiring diagrams provide precise instructions tailored to individual blower motor models. These diagrams ensure compatibility and accuracy, preventing incorrect connections. They include details like wire color codes, terminal locations, and specific control sequences. Always refer to the official manual or website for the correct diagram. For example, Goodman, Trane, and Carrier each have unique wiring configurations. Locate the model number on the motor to find the exact diagram. This ensures safe and efficient installation, adhering to the manufacturer’s guidelines. Using generic diagrams can lead to errors, so prioritize authentic, model-specific resources for reliable results.

Wiring for Variable Speed Blower Motors

Variable speed blower motors offer enhanced efficiency and control, requiring specific wiring configurations. These motors use advanced control boards and sensors to adjust speed. The wiring involves connecting the motor to a variable frequency drive or a smart thermostat. Ensure proper communication between components by following the manufacturer’s instructions. Use shielded wires to minimize interference. Typically, these motors have more terminals than single-speed models, so precise connections are crucial. Refer to the wiring diagram for details on high, medium, and low-speed settings. Proper installation ensures optimal performance, energy savings, and quiet operation. Always test the motor at each speed to confirm functionality after wiring.

Universal Replacement Blower Motor Wiring

Universal replacement blower motors are designed to fit various HVAC systems, offering flexibility in installation. These motors often have multiple terminals to accommodate different wiring configurations. When wiring, always refer to the manufacturer’s diagram for specific instructions. Typically, the process involves connecting the power supply, neutral, and control wires. Ensure proper connections to capacitors or control boards if required. Use appropriate tools like wire cutters and strippers for safe and secure connections. After wiring, test the motor at different speeds to confirm functionality. Always follow safety guidelines and manufacturer recommendations to avoid errors and ensure optimal performance.

Common Mistakes to Avoid

When wiring a blower motor, several common mistakes can lead to improper function or safety hazards. One of the most frequent errors is connecting wires incorrectly, such as reversing the neutral and power wires. Another mistake is ignoring the wire color coding, which can result in motor damage. Additionally, many individuals overlook the importance of consulting the wiring diagram specific to their motor model. Improper use of tools, such as using wire nuts instead of soldering, can also lead to loose connections. Finally, failing to test the motor after installation is a critical oversight. Always double-check connections and ensure the motor operates at all speed settings before finalizing the installation.

After completing the wiring process, it’s crucial to perform a final check to ensure everything functions correctly. Start by verifying that all connections are secure and match the wiring diagram. Turn on the power and test the blower motor at all speed settings to confirm proper operation. Check for any unusual noises or vibrations, which could indicate misalignment or improper wiring. Ensure that the motor responds accurately to the control signals, such as thermostat inputs. Finally, review all safety precautions and confirm that no tools or materials are left inside the system. A thorough final inspection will help prevent future issues and ensure reliable performance of your blower motor.